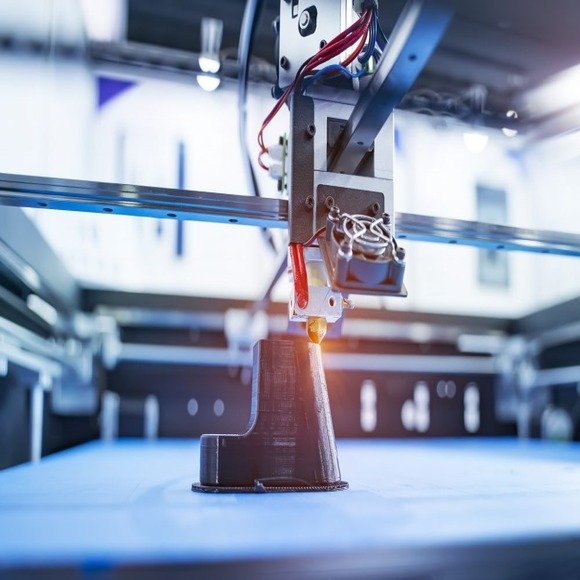

In our invariable mission of creativity and manufacturing excellence, IGS Engineering PTV Ltd has encouraged the transformative ability of 3D printing and additive manufacturing technologies. These advanced processes enable us to create highly complex structures and prototypes with unmatched design and freedom. It also allows quick loop and optimization of automotive components.

Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM) Systems

Employing high-energy lasers or electron beams, these best quality machines can directly fuse and build components from metal powders, including aluminium, titanium, and stainless steel alloys and are Ideal for producing high-performance, lightweight, and geometrically rough and tough automotive parts.

How 3D Printing and Additive Manufacturing Machines Work?

As the name suggests, Additive manufacturing involves building components layer by layer. It uses materials like plastics, metals, or composites. Overall, our facility houses several types of 3D printing and additive manufacturing systems, each with its unique capabilities and quality.

Fused Deposition Modeling (FDM) 3D Printers

These machines extrude and deposit thermoplastic materials like ABS or PLA, in a controlled manner to build parts layer by layer and are specifically Ideal for rapid prototyping, functional testing, and producing low-volume production runs.

Stereolithography (SLA) 3D Printers

More so, using a laser to cure and solidify liquid photopolymer resin, these printers can create highly accurate and detailed parts with smooth silk surface finishes which are commonly used for prototyping and producing patterns for investment casting.

Selective Laser Sintering (SLS) Systems

These machines use high-powered lasers to selectively fuse and sintered powdered materials like nylon, aluminium, or steel, into solid objects. These are capable of producing functional prototypes and end-use parts with excellent mechanical properties.

Production in Automotive Manufacturing

1. Rapid Prototyping

Rapid Prototype quickly creates physical prototypes to evaluate form, fit, and function. It also enables skillful design iterations and minimises product launch timeline.

2. Tooling and Fixtures

It produces custom jigs, fixtures, and tooling components with complex figures for more effective manufacturing processes.

3. End-Use Production Components

We manufacture lightweight, optimised components like air intake manifolds, cooling ducts, or structural brackets directly from 3D printing, reducing material waste and enabling mass customization.

4. Reverse Engineering and Spare Parts

It recreates legacy or obsolete components by 3D scanning and printing replacements and it facilitates maintenance and repair operations.

Moreover, by blending these advanced 3D printing and additive manufacturing technologies into our operations, we IGS Engineering are pushing the boundaries of automotive manufacturing by delivering progressive solutions to drive performance and sustainability for our partners.