Lathes are implied metalworking machines used for creating cylindrical components by removing material from a rotating workpiece. At our facility, we employ miscellaneous types of advanced lathe machines to produce precision-machined automotive parts with outstanding surface finishes and dimensional exactness.

Engine Lathes

These highly conventional lathes are specifically designed for Heavy duty and intensive work. The lathes that are used for heavy duty work and intensive usage in industries are categorized as heavy-duty lathes.

- Turning

- Facing

- Drilling

- Boring

- Threading

These operations are done on the cylindrical working on the working in cylindrical surface of the job. Some of the essential components that can be identified in this category include the bed, head stock which can rotate, and the tailstock where the workpiece will be supported. Engine lathes are versatile and require variety of applications in manufacturing the shafts, axles, pistons, and other cylindrical products.

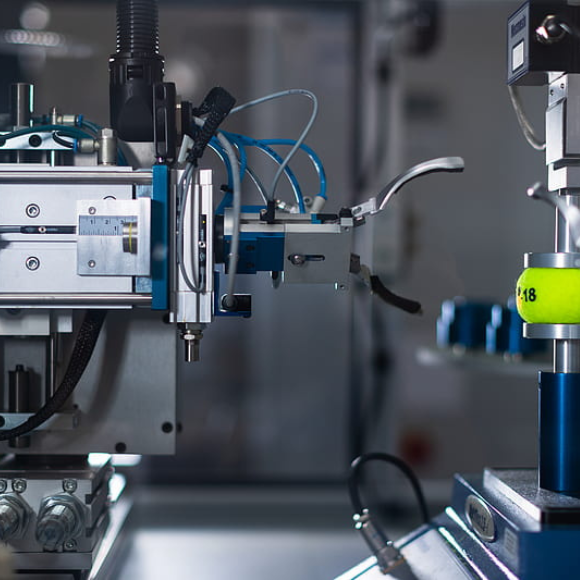

CNC Turning Centers

A turning centre is, in fact, an entirely computerised lathe and typically known as a Computer Numerical Control or CNC turning centres. Which are; These are run on a set of predetermined instructions that have been fed into a computer. These machines are more precise, can produce consistent output, and offer better through output than the traditional lathe. CNC turning centres can do contour turning and threading, drilling up to 5axial depth and even milling operations within a single set up.

Swiss-Type Lathes

Swiss-type lathes are designed for completing complex parts of small sizes with high precision and at the same time increasing the rate of production. They have several tooling stations and positional bushings for the extended straight or cylindrical workpieces. It also suits applications necessary for manufacturing car parts such as fuel injectors, valve guides, and shafts.

Vertical Turret Lathes (VTL)

This is a special type of turning or lathe where our skills were put to test and proved to be at their best.

When used, these, lathe machines as a part of making our manufacturing processes at IGS Engineering PTV Ltd more efficient, enable producer of a desired cylindrical parts, which offer quality standards as demanded in automotive industries.