Grinding and Polishing Machines

Grinding Machines

Grinding is an abrasive machining process used to achieve high precision, tight patience, and superior surface finishes on automotive components. At our facility, we employ eclectic types of advanced grinding machines for these binding operations.

Surface Grinders

We use it for precision grinding flat surfaces on components like brake discs, valve plates, and cylinder heads. Its reciprocating or rotary table movements allow for grinding complex shapes and patterns.

Cylindrical Grinders

It’s used to design grinding machines for the external diameters of cylindrical components, such as shafts, pins, and rollers. Some models also feature internal grinding capabilities for bores and internal diameters.

Centerless Grinders

These grinders support and rotate the workpiece between two grinding wheels without using centres or chucks and are ideal for high-volume production of cylindrical parts like bearings, bushings, and pins.

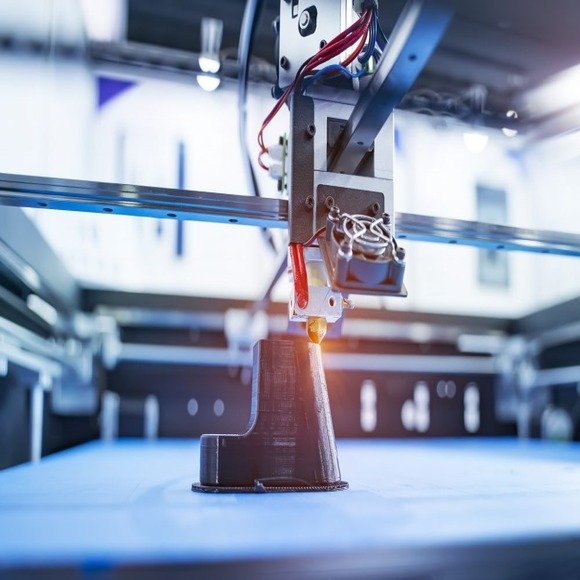

CNC Grinding Machines

Computer Numerical Control (CNC) grinders offer enhanced automation and flexibility. Using programmed tool paths, complicated 3D contours and geometries can be precisely ground.

Polishing Machines

Vibratory Finishing Machines

Lapping and Honing Machines

Our skilled professional operators and technicians closely monitor and optimise the grinding and polishing processes, considering factors like abrasive types, feed rates, and coolant application to guarantee the desired surface virtue and dimensional accuracy for each automotive component.