Here at our plant, we apply automation techniques in the manufacturing of cars to improve quality, precision, and efficiency. It is therefore crucial that its components are fitted with these systems since they are very essential in various processes. Right from factory gate, material handling to assembly, inspection, and so on is normally processed under our watchful eyes.

The correct procedure in the use of Robotic and Automation Systems:

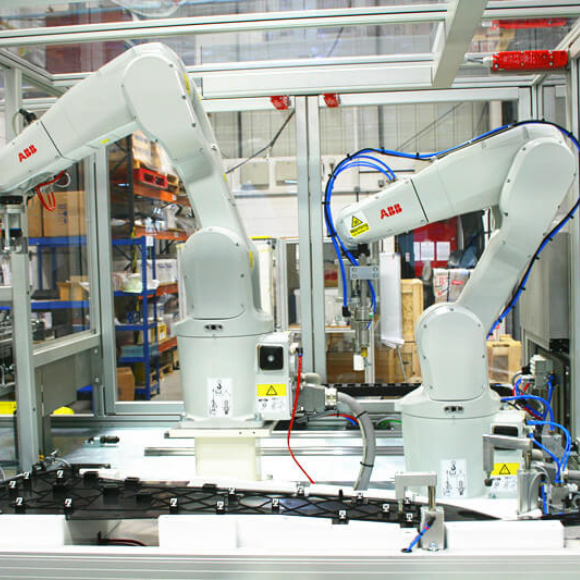

Robotic systems are defined as related series of programmable, multi axial tools built to execute certain operations with optimum accuracy. These robots may be incorporated with other devices for various uses at the terminal or mounting part of the arm, or tooling part of the arm, such as grippers, welding torches, or vision systems.

Automated systems are formed from the integration of a number of sub-systems that features a combination of robots, conveyors, sensors and control systems to produce a fully or partially completed automation line. These systems are able to perform routine tasks for longer periods with little or no interaction required from a human. That means it can produce a more consistent quality of work and improve the efficiency of a work process.

- Material Handling

They also utilize robots where applicable like loading/unloading machines, part transfer, stacking unstacking etc due to efficiency and less reliance on human workers.

- Welding and Joining

Welding cells for automotive structure are used to accurately stitch automotive parts with minimal soldering defects as they use programmed methods of welding.

- Machine Tending

Computer-controlled conveyors transport and retrieve parts to and from CNC machines, thereby making efficient use of machines and minimizing off-time between operations.

- Assembly and Pick-and-Place

Automotive parts that are most impossible to assemble are accurately positioned and aligned through robots which are programmed to assemble automobile components.

- Inspection and Quality Control

Automated inspection, robotic vision systems programming. Vision systems with specialized sensors are applied for inspection of parts and articles for defects and compliance with the required quality standards.

Integration and Programming

By monitoring, maintenance, and software updates which are crucial for maintaining the high performance and reliability of these advanced systems in our automotive manufacturing processes we take care of each process very carefully.