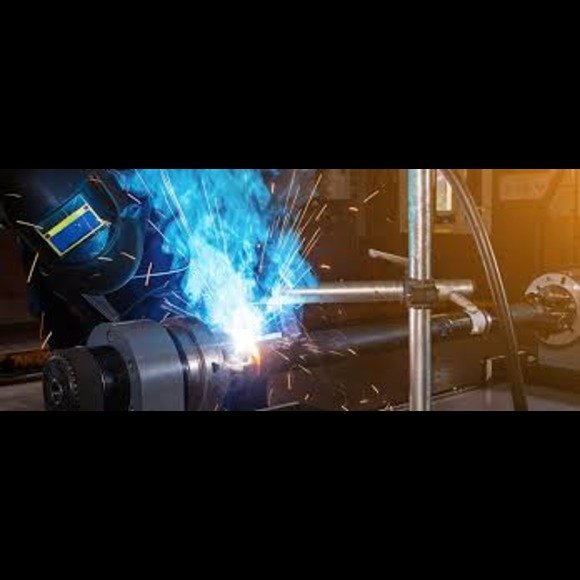

Of all manufacturing industries, automotive manufacturing relies significantly on welding as a major process. It welds the structures and parts of metallic materials and products. At IGS, we use various smart welding equipment and standards of welding for joining components that will not fail to meet the required quality.

How CNC Machining Centers Work?

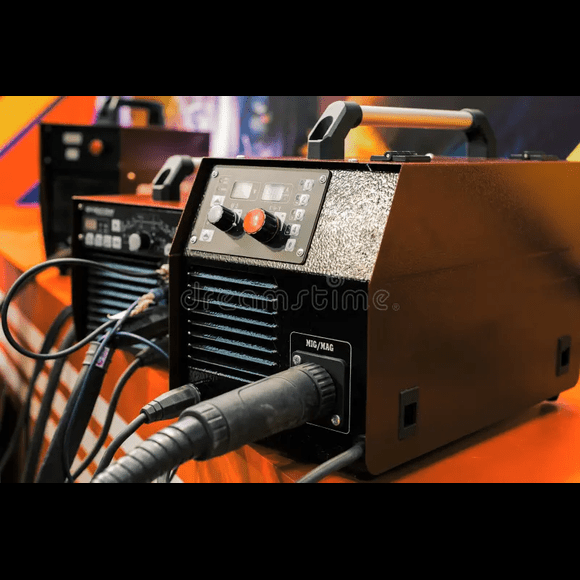

Arc Welding Machines

Gas Metal Arc Welding

These machines employ a consumable wire electrode and an inert gaseous envelope to make the weld.

Gas Tungsten Arc Welding

These units employ a non-consumable tungsten electrode and an inert gas to make highly accurate welding.

Shielded Metal Arc Welding

It is also commonly referred to as stick welding or pre-cur courtesy welding. These machines utilize a wastage electrode with a flux covering on top.

Resistance Welding Machines

Spot Welding

In this method, electrical current and pressure are focused to melting the overlapping areas and thus joining the metal sheets.

Seam Welding

They are used in a similar way to the rotating head or electrode head in order to produce a weld along a seam.

Laser and Electron Beam Welding

Laser Beam Welding

CO2 laser welding is another technique that employs high-energy laser beams in joining metals with deep penetration and minimal distortion.

Electron Beam Welding

Kathleen Titing has specialized in electron beams that produce welds in a vacuum for reactive materials.

Assembly Machines

Besides welding process, there are also additional assembly machines incorporated to fasten and connect automotive parts as well as assembling them in an accurate and proficient manner.

Robotic Assembly Cells

Automatic robotic hands include pick-and-place mechanical arms with end tools that perform fastening and joining activities.

Final positioning and alignment of the parts is made possible by employing the use of vision systems and sensors.

Automatic Assembly Lines

Structural connection to welding cells for joining welded sub-assemblies.

Hydraulic and Pneumatic Presses

Employed for force-fitting applications, buckle curling, engaging of electrical contacts, and any other application demanding a high clamping force.

Our welders and field technicians as well as engineers work hand in hand to enhance these welding and assembling processes. They guarantee that the quality, durability and adherence to the predefined industry standards for automotive parts and systems are maintained consistently.